Robotics

Industrial robots enhance manufacturing efficiency

Industrial robots are transforming manufacturing efficiency by performing repetitive tasks quickly and accurately. These machines reduce labor costs and minimize human error, allowing for continuous operation and increased production rates. With advancements in artificial intelligence, robots can adapt to changing conditions, optimizing workflows in real time. By integrating robotics, manufacturers enhance productivity and gain a competitive edge in the market.

Structured curriculum

Design thinking

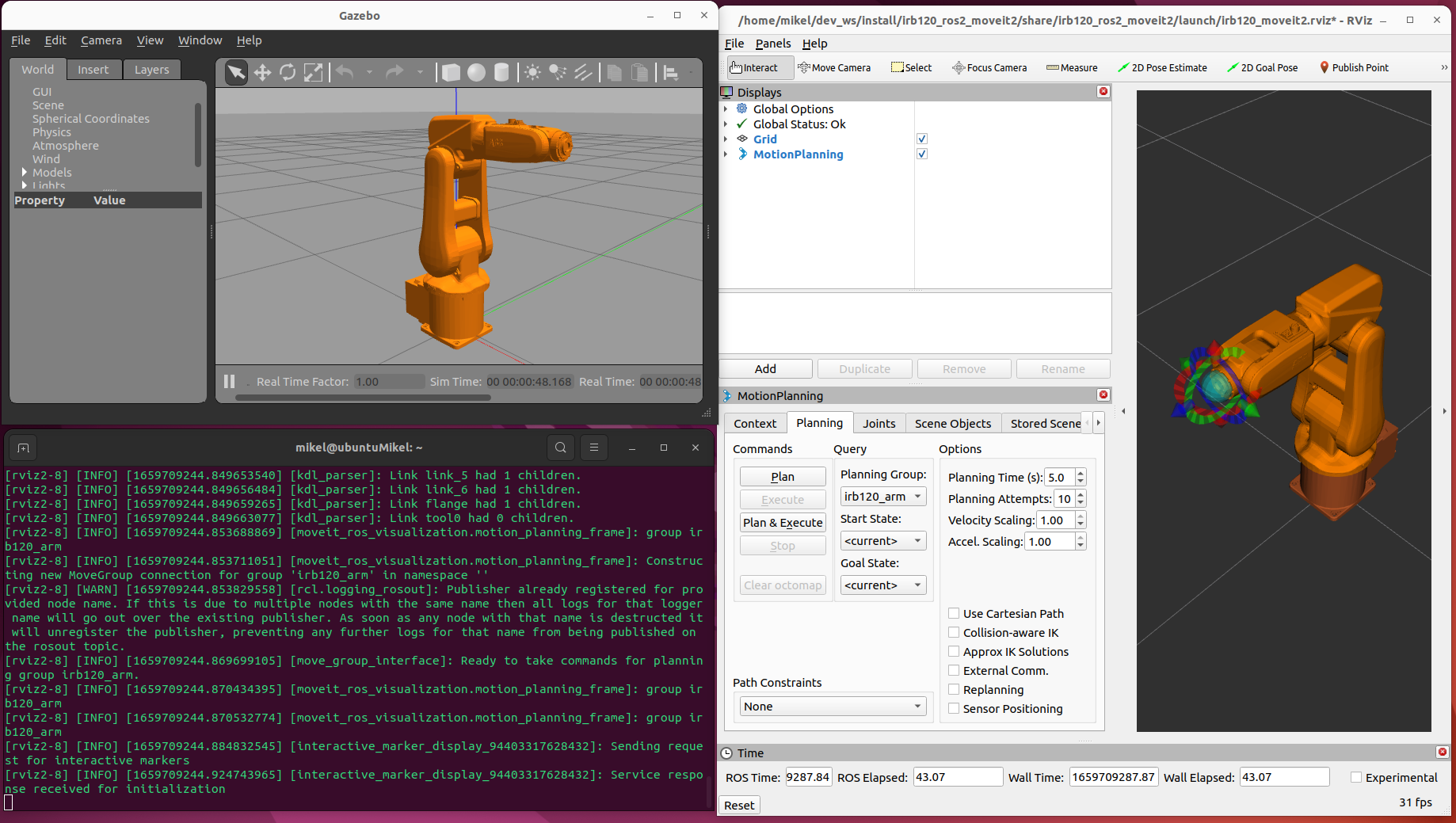

Immersive simulations

Hands-on projects

Team-based challanges

Real-world applications